Hand Made Real Blades for Japanese Samurai Sword

- Stock: In Stock

- Model: BL0

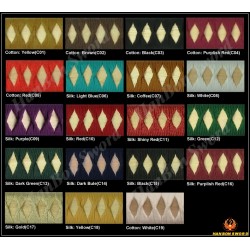

Available Options

Please make up your own mind on what types of steel best suit your preference (and budget) in a sword. It just depends on what you are looking for in a blade, what you like and your intended usage. A sword made from stainless steel is almost for decoration or kitchenware, we have no stainless steel blades.

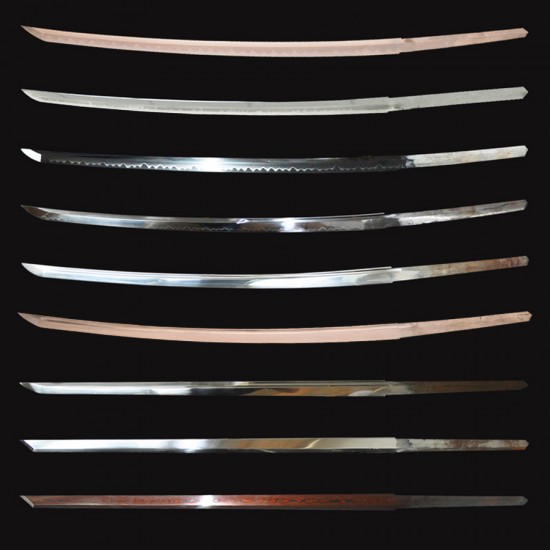

BL01: 1060 High Carbon Steel Blade

1060 carbon steel is a fairly basic steel with only Carbon and Manganese added to the Iron, has the lowest practical carbon content of 0.60%. 1060 steel is inexpensive and relatively easy to grind and work with. It offers a great compromise between hardness (edge holding ability) and pliability (strength), so 1060 Carbon Steel swords are very popular. Manganese is added to prevent this blade from rusting, but It is not stainless though and steel needs to be oiled and maintained regularly.

Advantages:

· The steel offers a good compromise between hardness and pliability

· Simple steel, easy to use during play or practice, easy to maintain

· Affordable prices, some models are sold around US $90+, including shipping

· Can cut through water filled bottles, tatami , fresh green bamboo etc.

· Can be folded to create thousands of layers

Disadvantages:

· Has the lowest practical carbon content of 0.60%

· 1060 steel will probably not make it hard enough, it will bend easily and not keep an edge

· Other steel also offers the same hardness such as 9260 steel, but also more flexibility

------------------------------------------------------------------------------------------------------------------------------

BL02: 1095 High Carbon Steel Blade

1095 is sort of the "standard" carbon steel, it is categorized on the basis of 0.95% carbon. 1095 qualifies as a high-carbon hardened steel. It offers the highest carbon content, it yields the sharpest edge. Toughness, hardness and durability make 1095 steel the most-popular choice for swords. 1095 Carbon steel is very HARD - and unless it is properly heat treated, this hardness can sometimes be problematic when used on harder targets. When tempered properly, 1095 steel is great for swords as when it is clay tempered.

Advantages:

· Provides reasonably toughness, more durability, holds an edge well

· Extreme hardness, workability, easy sharpening, not too expensive and performs well

· 0.95% carbon is a lot of carbon in the metal though, it doesn't bend all that well, even after tempering

Disadvantages:

· It will rust easily if not clean and dry the blade thoroughly, it depends who makes and treats the steel

------------------------------------------------------------------------------------------------------------------------------

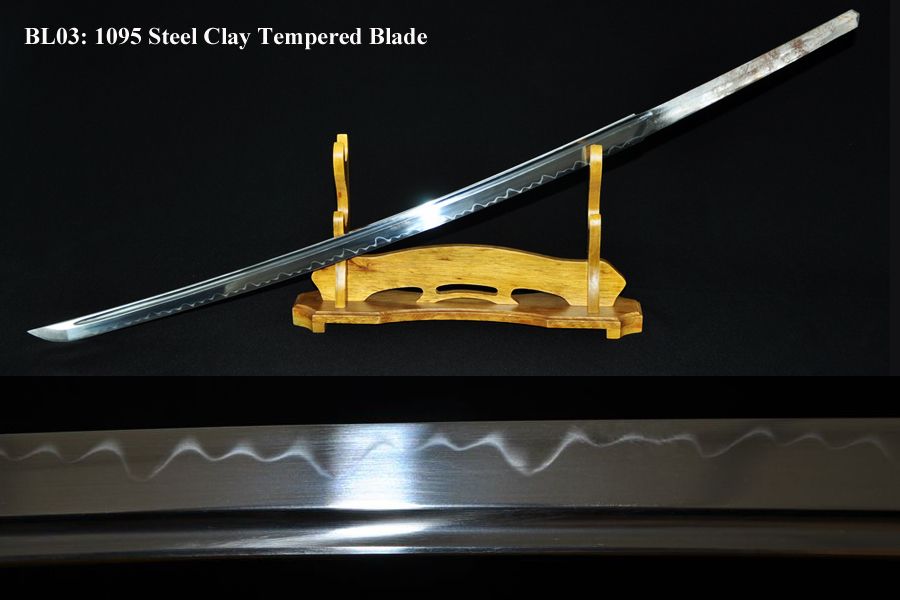

BL03: 1095 Steel Clay Tempered Blade

This blade is 1095 high carbon steel with clay tempered. Clay-Tempered is the process of using clay to insulate the parts of the metal that you want softened so that when the sword is heated and quenched, they cool more slowly. The edge of the blade still retains more of its hardness than the rest of the sword because of the clay-tempering process that it went through. You can actually see the difference in hard and soft metal because there is a visible temper line on the blade, also called the hamon (beautiful curves). Clay treatment has to be operated by professional to be efficient. The end result is an incredibly crafted blade that has both strength and flexibility, which is the hallmark of a high-quality sword.

Advantage:

· Clay-Tempered strengthen the hardness, durability and resistance of the blade

· The hamon (a visible temper line) makes the blade very beautiful

Disadvantage:

· Has to be operated by professional and precise hand-crafted processes

· Relatively high prices, some models are sold around US $200+

------------------------------------------------------------------------------------------------------------------------------

BL04: 1095 Steel Unokubi Blade

This blade is 1095 high carbon steel. There are two blood grooves on each side of this blade (Unokubi Blade). 1095 qualifies as a high-carbon hardened steel. It offers the highest carbon content, it yields the sharpest edge. Toughness, hardness and durability make 1095 steel the most-popular choice for swords. 1095 Carbon steel is very HARD - and unless it is properly heat treated, this hardness can sometimes be problematic when used on harder targets.

------------------------------------------------------------------------------------------------------------------------------

BL05: 1095 Steel Unokubi Straight Blade

This blade is 1095 high carbon steel, it is staight blade with two blood grooves on each side (Unokubi blade).

------------------------------------------------------------------------------------------------------------------------------

BL06: 1095 Steel Clay Tempered Unokubi Blade

This blade is 1095 high carbon steel with clay tempered.

------------------------------------------------------------------------------------------------------------------------------

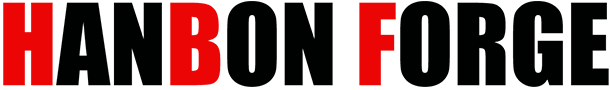

BL07: 1095 Steel Hazuya Polishing Blade

This blade is 1095 high carbon steel with clay tempered. It was hand polished by HAZUYA which is a very thin Uchigumori stone fixed with paper, Hazuya is a specific stone to bring up hamon, the stone is very fine and soft against the steel. The work is done to get mirror-like surface on shinogi-ji and edge. Hazuya polish is usually considered a more honest polish for inspecting the blade's tempering process. Advantage:

· The hazuya polish greatly broadens the viewing angle of the hamon, looking rather nice

------------------------------------------------------------------------------------------------------------------------------

BL08: 9260 Spring Steel Blade

9260 Spring Steel (also called Silicon Manganese Steel) consists of 2% silicon content, giving it an even more dramatic resilience against lateral bends and allowing it to spring back to true even after being bent almost to 90 degrees.

The 9260 spring steel has a significantly increased fatigue resistance compared to its nearest similar standard 1060 carbon steel. 9260 has the capability to be a harder blade, the incredibly crafted blade that has both strength and flexibility makes a high-quality katana sword.

Advantages:

· Capable to take 90 degree bend and still returning true

· 9260 Spring Steel have a reputation for durability, has both strength and flexibility

· Able to hold an edge and keep it

Disadvantages:

· The silicon makes 9260 Steel succeptible to decarburization, and it will react unfavorably if forged too cold, it will crack.

------------------------------------------------------------------------------------------------------------------------------

BL09: Folded Steel Blade

A folded steel blade is typically made from high carbon steel. The difference is that its process is the folding of the steel, where the swords are made by repeatedly heating, hammering and folding the metal. Our folded steel blade is folded 13 times creating 8192 layers. Folded steel makes the blade a better cutter and more durable.

Advantage:

· folded steel makes the blade a better cutter, flexibility and more durable

· nicer look and beauty (awesome visible pattern)

Disadvantage:

· If folding when done quickly and without serious attention to detail, this weakens a blade.

------------------------------------------------------------------------------------------------------------------------------

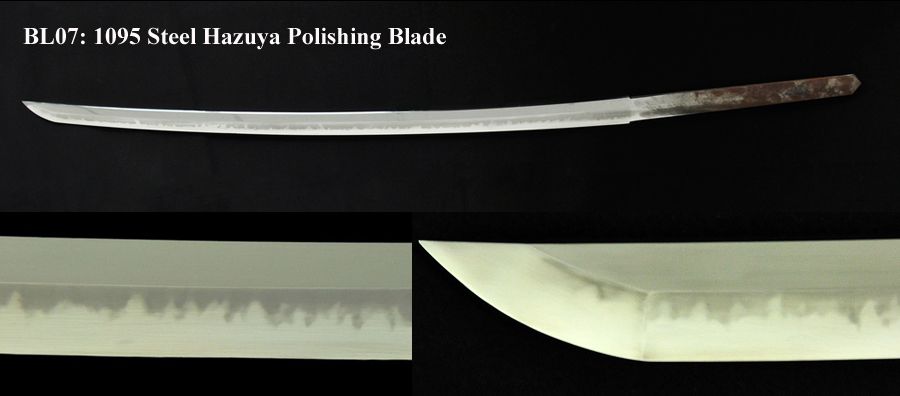

BL10: Folded Steel Straight Blade

Folded steel blade is constructed by forging and folding 1060 carbon steel together 13 times. This process is carried out until there are up 8192 layers, creating beautiful grain like patterns in the steel. Using the fold forging method was to tranaform iron in to high quality steel and make the blade more strong. This is a straight folded steel blade.

------------------------------------------------------------------------------------------------------------------------------

BL11: Black Color Blade

The blade of the sword has been constructed from 1060 high carbon steel. The whole blade was hardened by oil quenched. After sharpening, the black color is acquired after a specific treatment (electroplating) applied on the blade surface.

Advantage:

· The black color can prevent blade from rusting.

Disadvantage:

· It is not suitable to cut very hard things, or the black color will be worn off.

------------------------------------------------------------------------------------------------------------------------------

BL12: Black Straight Blade

------------------------------------------------------------------------------------------------------------------------------

BL13: Red Folded Steel Blade

This sword is made of damascus folded pattern steel (13 times folding to create the 8192 layers) with special treated, which creats many red and black pattern on the blade. The pattern not only looks beautiful but can prevent the blade from rusting.

Advantage:

· The pattern color can prevent blade from rusting.

Disadvantage:

· It is not suitable to cut very hard things, or the ed and black color will be worn off.

------------------------------------------------------------------------------------------------------------------------------

BL14: Red Folded Steel Unokubi Blade

------------------------------------------------------------------------------------------------------------------------------

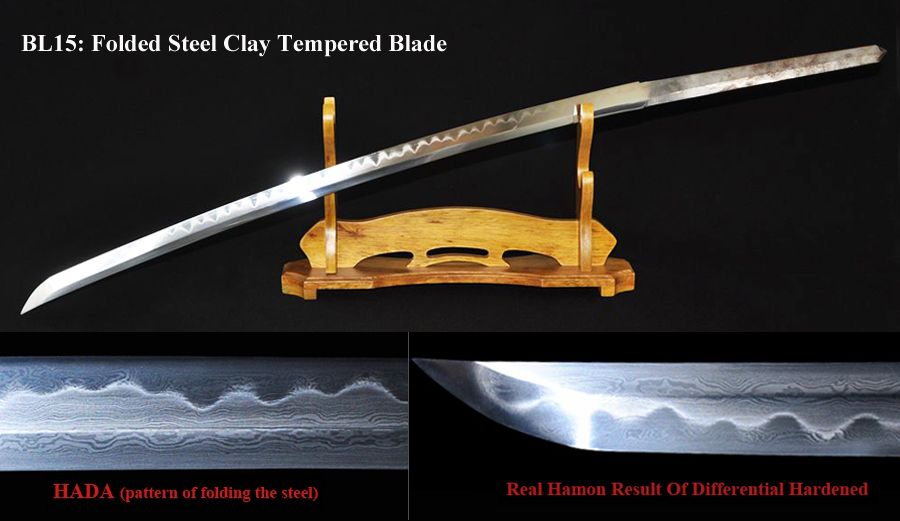

BL15: Folded Steel Clay Tempered Blade

------------------------------------------------------------------------------------------------------------------------------

BL16: Folded Steel Clay Tempered Blade (double hi)

------------------------------------------------------------------------------------------------------------------------------

BL17: 1095 Steel Clay Tempered KIRIHA ZUKURI Blade

------------------------------------------------------------------------------------------------------------------------------

BL18: 1095 Steel Clay Tempered KIRIHA ZUKURI Blade (S)

------------------------------------------------------------------------------------------------------------------------------

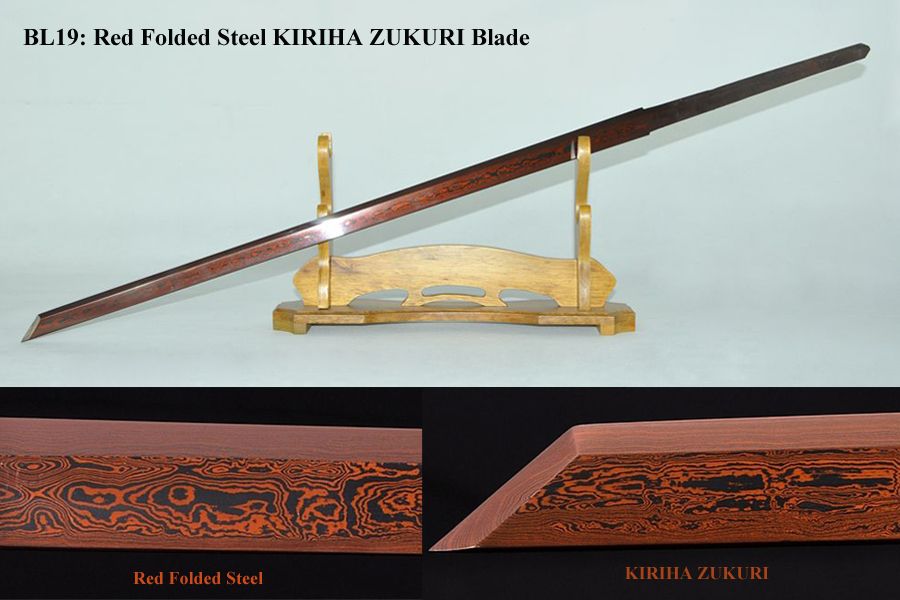

BL19: Red Folded Steel KIRIHA ZUKURI Blade

------------------------------------------------------------------------------------------------------------------------------

BL20: Red Folded Steel Sakabato (reverse-edged blade)

------------------------------------------------------------------------------------------------------------------------------

BL21: Kobuse Blade (Folded steel+1095 steel)

The construction of the blade is GYAKU-KOBUSE, one kind of KOBUSE construction, It is constructed of two different kinds of steel, the core steel and the outer steel, where the core steel is wrapped with the outer steel. the core steel is harder than the outer steel.

The outer steel was made of folded steel. It was folded 13 times creating 8192 layers for superior strength and flexibility. The visible tenuous undulating grain on the blade was resulted from folded repeatedly during forging. The core steel was made of 1095 steel.

The steel has been throughly refined and tempered, a special clay is applied to the blade by hand, using a thin covering near the edge and a thicker layer over the rest of the blade. This results in a relatively quicker cooling of the edge during quenching, producing a hard edge and softer back. The beautiful real hamon on the blade is also result of the differential cooling of the blade (quenching and tempering).

This blade has been hand polished with multiple grade sharpen stone by Japanese method, which made the surface of the blade like a mirror, the more importance is that the blade was polished by HAZUYA which is a very thin Uchigumori stone fixed with paper, Hazuya is a specific stone to bring up hamon, the stone is very fine and soft against the steel. the blade of this sword is completely finished with Hazuya. the work is done to get mirror-like surface on shinogi-ji and edge.

---------------------------------------------------------

Shipping Method:

US, Canada, France and Germany Orders: EMS (Worldwide Express Mail Service)

Other Orders: UPS Express or DHL Express

---------------------------------------------------------

Shipping Cost:

US, Canada, Australia, France and Germany Orders: FREE Shipping

Other Orders: $45USD per Sword

---------------------------------------------------------

Processing Time (Handmade by Order)

Normal Orders: 1 - 2 business days

Custom Orders: 3 - 5 business days (Standard Length Blade and Handle)

20 - 30 business days (Non-standard Length Blade and Handle)

Notes: For some high-performance swords may require longer handmade processing time, depending on the difficulty of the craft.

---------------------------------------------------------

Estimated Delivery Time

5 - 10 business days (US, CA, FR, DE Orders)

10 - 15 business days (Other Orders)

---------------------------------------------------------

Click Here to view More Shipping Information.