The standard of a good sword is not about hardness

The earliest weapons of mankind evolved from stone tools to the Bronze Age. At first, bronze wares were made by casting. Therefore, Chinese people called swords as cast swords. However, after entering the Iron Age, most of the steel casting structures are very brittle. , It is not suitable to bear the impact force, and must be forged and heat treated to improve its structure and properties. Forging can not only refine the structure, but also remove the impurities in the structure, and make the internal structure of the material be fibrously distributed along the stretching direction. Therefore, mankind began to research the technology of forging and smelting steel. Metal casting is easy to be mixed with bubbles and slag. Influencing the strength, mankind invented the technology of smelting and forging steel. All steel weapons are forged instead of the original bronze clay casting. Therefore, it is already wrong to call the method of manufacturing steel swords by casting swords.

Even today, steel swords still have a contradictory problem that is difficult to overcome, that is, the dilemma between hardness and toughness. The carbon contained in steel has no time to diffuse and migrate after quenching (quick cooling) It is forcibly restricted to the lattice of iron atoms, which causes distortion of the atomic lattice and destroys the distribution of carbon in the equilibrium state. When the carbon content reaches a certain level, a hard and brittle structure is produced. Material science It is called martensitic structure in China. As the amount of carbon increases, the brittleness increases, which affects the impact resistance of the sword. If you want to maintain the toughness of the steel, you have to sacrifice its hardness. It is not sharp enough, and even rolls up after cutting a hard object. This dilemma between hardness and toughness is the biggest issue faced by all swordsmiths at home and abroad, ancient and modern.

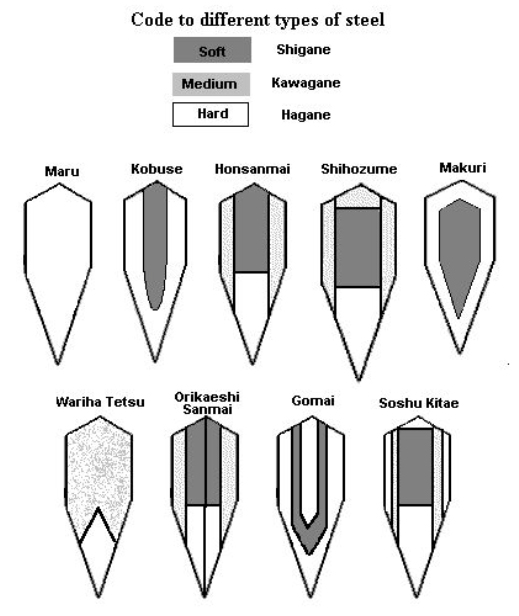

The cross-section structure of the katana, called kobuse in jargon, is to wrap high-hardness steel with low-hardness iron to achieve the best balance between hardness and toughness.

Hardness index: We have done hardness tests on all the swords involved. This time the tests are as follows:

1. Steel clamping (55.5 degrees) The swords involved include steel clamping, ordinary all-steel burnt blades, and no floor-clad steel.

2. Machine folding 3 pieces (57 degrees) The involved swords are organically folded 3 pieces combining Chinese swords and Japanese swords.

3. Ordinary recovery (57 degrees) involves swords; all patterned swords of recovery level.

4. Sifang forging (test hardness 62, but return to 60 degrees for the sake of safety) Involving swords; Sifang forging Japanese swords, super recovery Chinese swords.

Based on the physical characteristics of the sword, if the force limit of the sword itself is exceeded during use, any sword will bend or break. If it is tough, it will bend, and if it is hard, it will break. The two trade-offs are toughness. That is to say, a good sword should be bent rather than bent. A slightly bent sword is better than a sword handle, and even among the so-called top treasures in Japan, there is no "unbent" sword at all.

Now, more and more people like custome sword, just want to choose their favorite blade

Too many swords friends ask straightaway, "How hard is your sword, can it reach 60HRC". Hardening is very simple, reducing the hardness to increase toughness, maintaining sharpness, and not easy to rewind is the difficulty. The suitable hardness for combat swords is 55-59. It can be strengthened by about 2 degrees by covering the earth and burning the blade. Generally, it will be controlled within 60HRC for safety. So there is no need to use hardness as an indicator of the quality of a sword, don't be persistent.

Want a unique sword? Feel free to contact us:

Phone: 086 13739276006

Email: [email protected]

Website: www.hanbonforge.com

Custom Sword Page: www.hanbonforge.com/CUSTOM-SWORDS/Custom-Your-Own-Swords

Leave a Comment