About polishing the Japanese samurai sword

A traditional Japanese sword is not complete because the blade has been forged, the metal has cooled, and the soil has been removed. Polishing is a key step to complete a sword. To learn more about polished Japanese swords and how to make them, please read on.

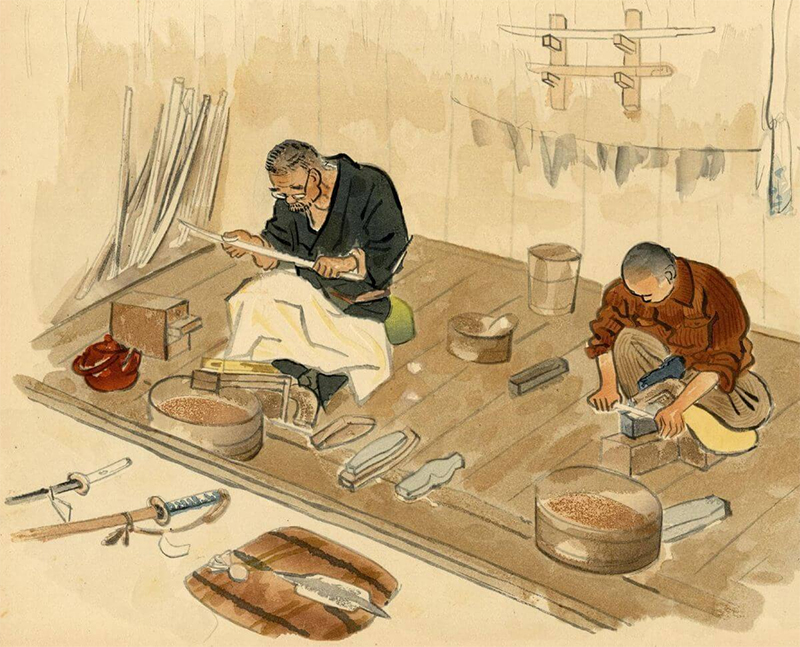

1) Sharpening expert

It is not the swordsmith who polishes the sword. Instead, an expert called togishi is responsible for this task. In the past, togishi traditionally used three types of stones to polish the sword. However, today, togishis uses more than a half dozen.

2) Polishing takes a lot of time

You might think that polishing Japanese swords is a quick and simple process that can be done in just a few minutes. However, it is not. In most cases, polishing takes longer than the actual forged blade. A typical polishing job takes about 2 to 3 weeks. This is a time-consuming and methodical process, which is why there is an expert to complete this task.

3) Improper polishing will damage the blade

Polishing the sword helps to improve the sharpness and beauty of the sword. However, improper polishing can have a serious impact on the sword, and may even damage or destroy it. If togishi changes the geometry of the blade and/or wears the steel excessively, it will destroy the function and value of the sword.

4) Glazing

One of the processes for polishing traditional Japanese swords is glazing, which involves the use of fine-grained polished stones to achieve a mirror finish on the blade. However, for the blunt blade of the sword, togishi strives for a matte effect to make Harmon more visible and attractive.

5) Polishing provides "insight" for sword production

A carefully polished Japanese sword can reveal various information about its manufacturing method. For example, it reveals the speed at which the cutting edge cools; what is the temperature at which the blade cools? Even the carbon content of the steel itself. Of course, these findings are only visible in well-polished blades. If the blade is not polished or poorly polished, these features cannot be identified.

6) All polishing agents must be removed

Once the sword has been completely polished, togishi must remove any trading volume of oil. Even a small amount can damage the blade by promoting rust and corrosion. The salt in the polishing oil provides an ideal breeding ground for mold and mildew, which in turn can lead to corrosion.

Discover the many attractive options available for Katana swords and custom swords.

Want a unique sword? Feel free to contact us:

Phone: 086 13739276006

Email: [email protected]

Website: www.hanbonforge.com

Custom Sword Page: www.hanbonforge.com/CUSTOM-SWORDS/Custom-Your-Own-Swords

Leave a Comment