Samurai Sword Blade Niku

04 Jul

1 Comment(s)

11445 View(s)

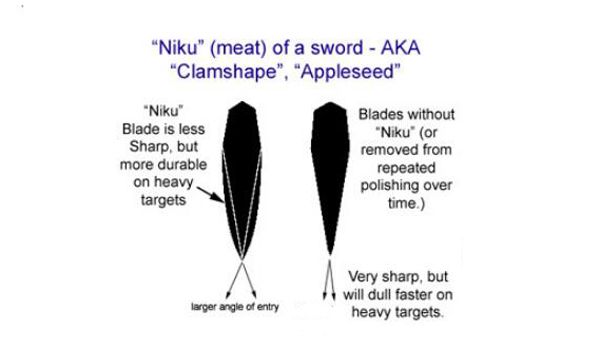

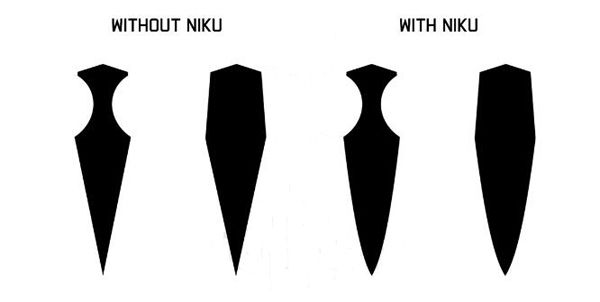

'Niku', which is basically the Japanese word for 'meat' - the meat on the bones of a sword. It is the amount of roundness and curvature of the ji surface, used to describe the tendency of a traditional Japanese blade to have a bulging cross section on the side surface. Niku is distinct from thickness of a blade, or the kasane. A thick blade with a flat ji surface has no niku.

In fact, one method of dating blades is to determine how much of the niku has been worn away through repeated polishing. A sword with much niku simply means that a sword has not been polished very often. With every sword polish, the steel of the sword is reduced. By adding a little bit of meat to the cutting edge from the start, it will extend the life-time of a sword drastically. The more niku a blade has, the greater its ability to absorb to shock and impact. This is far better for cutting and cleaving through armour and bone, however the ji (rounding of the blade's surface) means that the ha (blade edge) will never be as sharp as that of a blade that has less niku.

For example, the tool axe has a strong sideways force to allow easy splitting of the wood due to its geometry, which is designed to cut hard objects. What you can't do is cut flexible objects that require slicing through a top layer such as a tomato.

The presence of niku will strengthen the cutting part of a differentially hardened blade simply by adding more mass. We can conclude that niku is in inverse proportion with the razor sharpness of a blade. The sharpest edge, and thus the most likely to chip and break, is the hira-zukuri style blade. This is practically razor – wickedly sharp, but impractical for hard targets.

Want a unique sword? Feel free to contact us:

Phone: 086 13739276006

Email: [email protected]

Website: www.hanbonforge.com

Custom Sword Page: www.hanbonforge.com/CUSTOM-SWORDS/Custom-Your-Own-Swords

Phone: 086 13739276006

Email: [email protected]

Website: www.hanbonforge.com

Custom Sword Page: www.hanbonforge.com/CUSTOM-SWORDS/Custom-Your-Own-Swords

1 Comment(s)

Hello, I am looking for a katana with the following criteria.

Blade length (with Habaki): approx. 73-74 cm

Blade Construction: Honsanmai or Shihozume with Hamon

Niku blade shape without fuller (Bo-Hi)

Do you have such a scissors in your range, or can you finish it?

If so, please send me detailed description and the Price inc. shipping to germany

Many regards Markus

Leave a Comment