Bronze Sword VS Iron Sword VS Steel Sword

The sword is one of the most iconic weapons in history. It is classified as a long-bladed weapon used for logging and/or thrust, and its history can be traced back to 1600 BC.

Although swords are made of many metals, the most common ones include bronze, iron, and steel. So, which of these metals is the best?

Bronze sword

Some of the earliest swords in the world were made of bronze. It is true that before bronze, various civilizations had made sharp blade weapons from materials such as flint and rock, but the Bronze Age set new standards for weapons. The swordsmiths of this era made bronze swords by mixing copper with various alloys, the main alloy being tin.

Unfortunately, bronze did not produce particularly high-quality weapons or armor, including swords. Bronze swords are brittle and often break on impact.

Another disadvantage of the bronze sword is its rarity. Because it requires a considerable amount of tin-a rare metal-ancient civilizations could not easily mass-produce bronze swords and weapons for their armies.

The only real benefit of the bronze sword is its resistance to rust and corrosion. Bronze will rust over time, although it usually does not rust on metal.

Iron sword

Although they first appeared around the 12th century BC, iron swords were not widely produced or otherwise obtained until the 8th century BC.

In terms of performance, the iron sword is slightly improved than the bronze sword. The iron sword is slightly stronger, and it is not easy to break or bend when used. In addition, the more times the iron is processed and repaired, the harder it becomes. If the iron sword is repaired frequently, it will become stronger.

In addition, iron is easier to obtain than tin, which makes it easier and more cost-effective for ancient civilizations to equip their armies with iron swords instead of bronze.

Steel sword

The emergence of steel technology makes the sword more durable. The swordsmith discovered that adding coal (carbon) to iron during the smelting process produced a new and improved alloy: steel. There are other changes in the production process, including the use of quench hardening technology instead of work hardening.

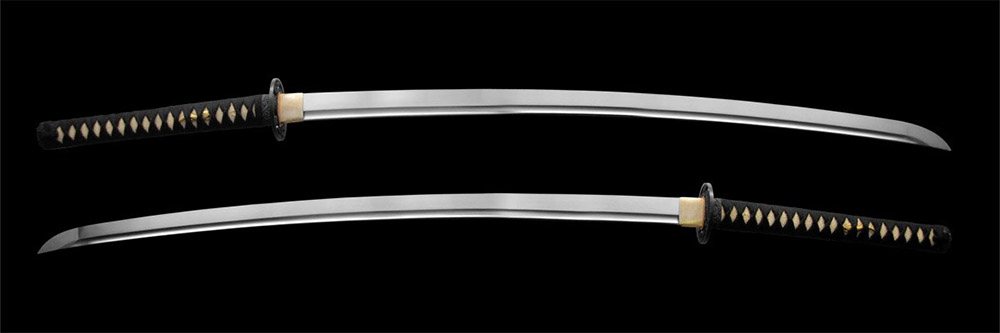

From a quality point of view, steel swords are (and still are) unparalleled in terms of strength and durability. They are stronger, more durable, more resilient, and can be forged into many different shapes (bronze swords are cast while steel swords are forged).

Of course, most modern swords are made of steel because of their high quality. From the Japanese katana sword to the Korean sword, steel is the metal of choice for sword making.

Discover the many attractive options available for Katana swords and custom swords.

Want a unique sword? Feel free to contact us:

Phone: 086 13739276006

Email: [email protected]

Website: www.hanbonforge.com

Custom Sword Page: www.hanbonforge.com/CUSTOM-SWORDS/Custom-Your-Own-Swords

Leave a Comment