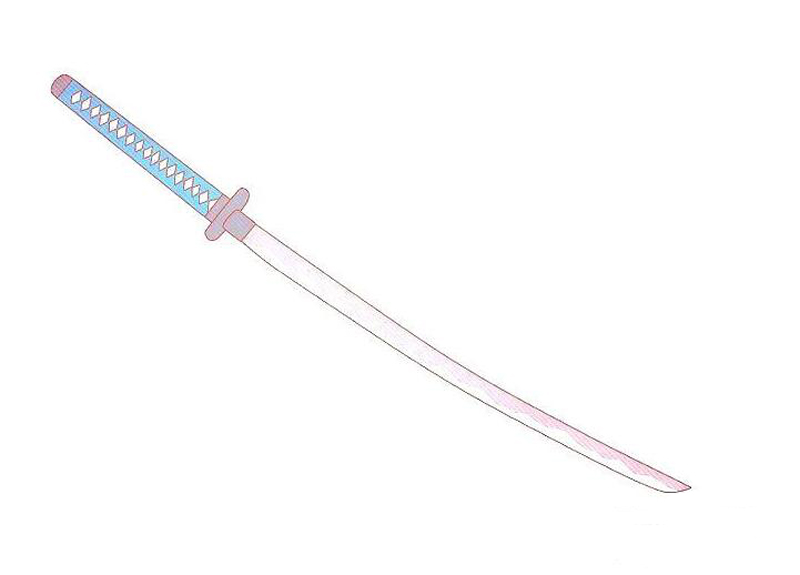

How to forge your own katana swords?

05 Dec

0 Comment(s)

3622 View(s)

1. Buy or find a piece of steel about 2 inches (5.1 cm) wide and 5 inches (1.27 m) thick, slightly over 3 feet (0.9 m) long.

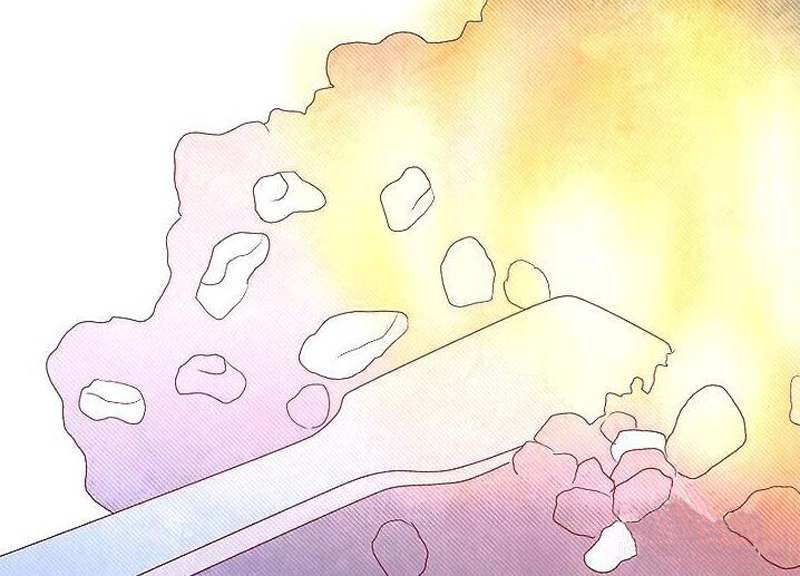

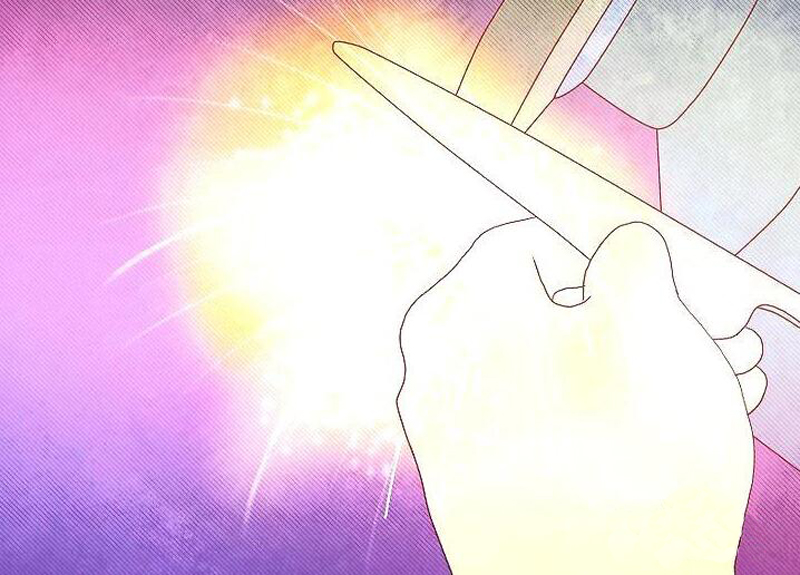

2. Heat steel in a furnace or open hearth. You must heat the material to a temperature close to 1600 degrees Fahrenheit (870 degrees Celsius) to forge and remove impurities. During the heating process, substances such as sulfur and silica are oxidized and separated from the iron to form slag. The removal of slag greatly enhances strength of steel.

3. Pull the heated material out of the furnace, showing yellow-orange color, and put it on the anvil.

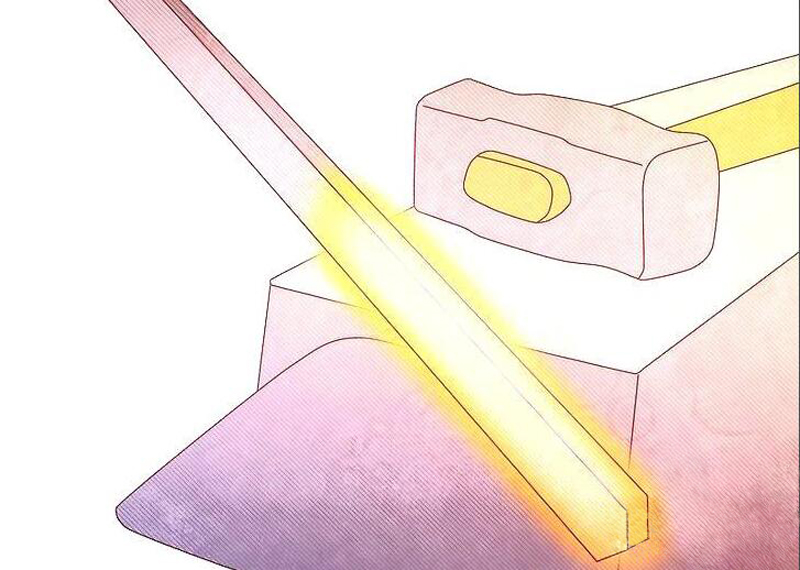

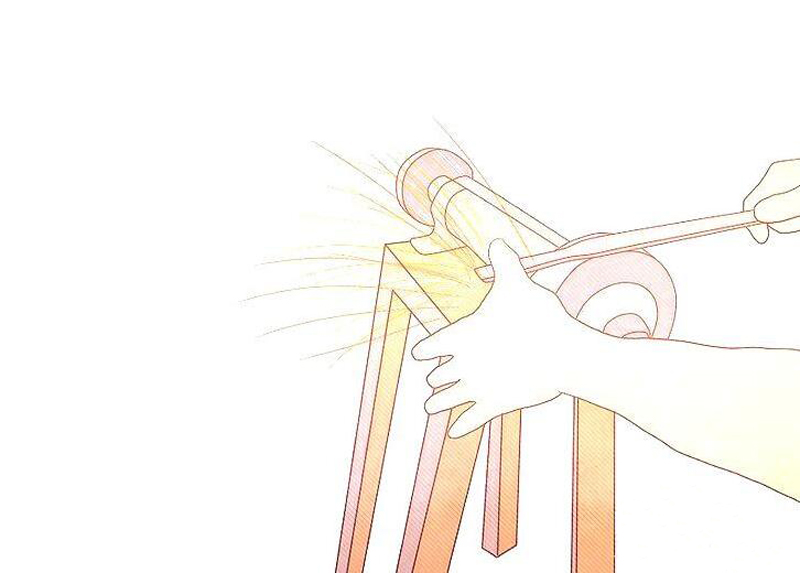

4. Forge steel. Hit the material with a hammer and turn it during forging. During the forging process, the material needs to be reheated to maintain its plasticity. The material is bent and chiseled on the anvil to form a blade shape.

5. Use the grinder and file to form the final shape of the blade.

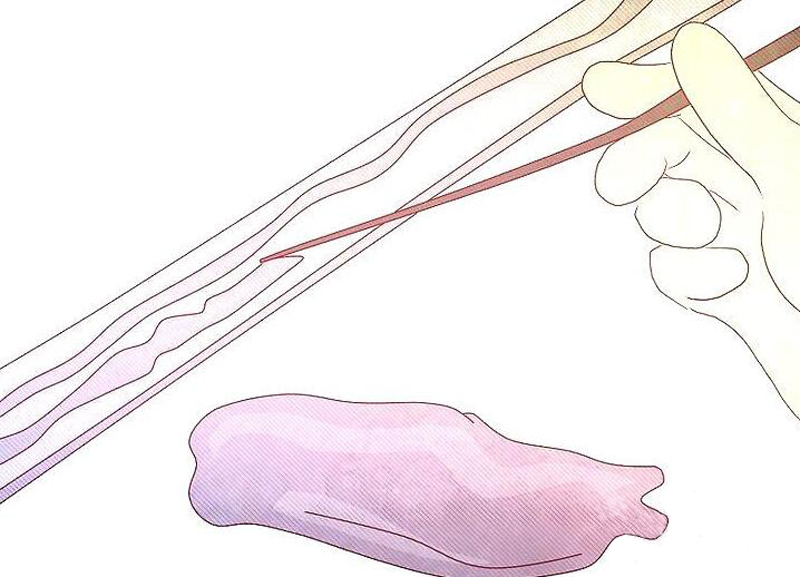

6. Treat the blade with a special clay mixture. You can add clay and other substances, such as grass and feathers in order to achieve the desired results. Apply the mixture to the spine of the blade so that most of the edges are untreated. This will help to make the spine flexible and sharp on the edges. Reheat the blade during forging.

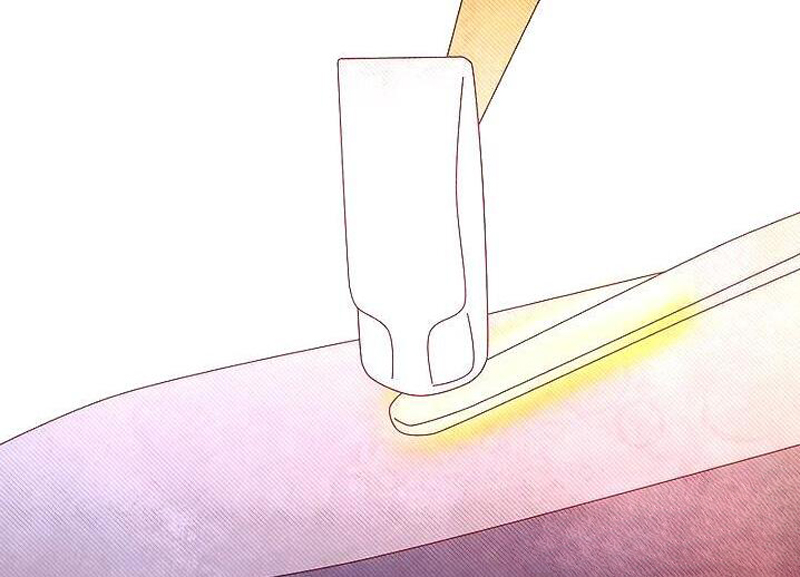

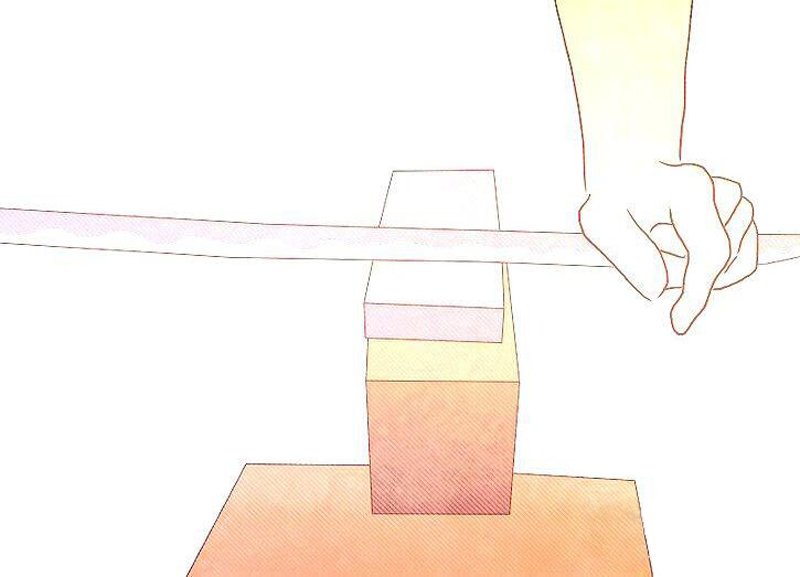

7. Dip the blade into water or oil along the edges and tip. Quenching technology is very important because the faster you cool the blade, the harder it becomes.

8. The blades were heated to about 400 degrees Fahrenheit (204.4 degrees Celsius) after quenching and then cool to room temperature. This process helps to balance the flexibility and stiffness of blade.

9. Remove the clay mixture from the blade and grind until sharp.

10. Sharpen with water. When polishing is completed, the hardened portions of the blade become apparent.

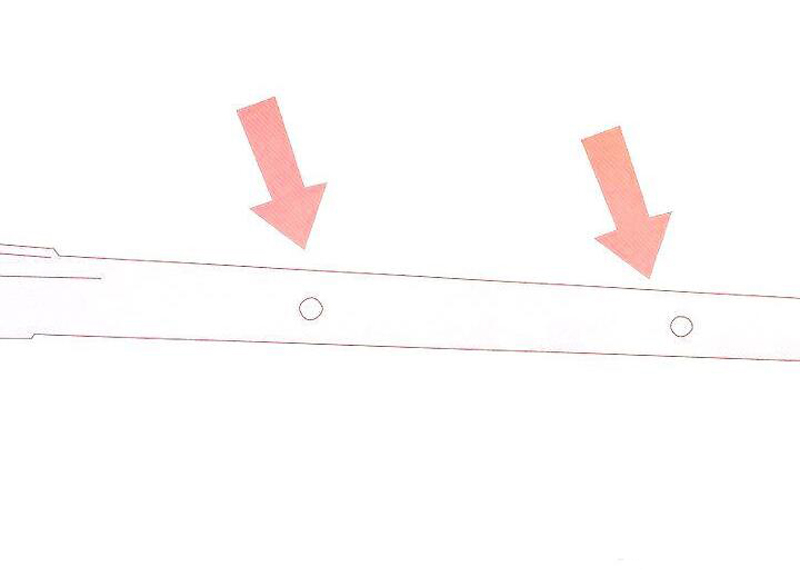

11. Drill two holes in the bottom of the blade to help secure it to the handle.

12. Make a handle with hardwood. The handle must be long enough to fit the hands and provide the best balance when connecting to the blade. A quarter of the wood provides maximum strength at the end. Wrap the handle with rayskin and ito. Install two pegs, habaki, seppa and guard. They will fix the sword.

13. Fix the blade on the handle.

Want a unique sword? Feel free to contact us:

Phone: 086 13739276006

Email: [email protected]

Website: www.hanbonforge.com

Custom Sword Page: www.hanbonforge.com/CUSTOM-SWORDS/Custom-Your-Own-Swords

Leave a Comment